Diagnostics Reveal an Easy Fix

Diagnostics - What Separates Handymen from Experts

Whenever digging into a troubleshooting and diagnostics project, its easy to get overwhelmed. You’re working off the word of a typically-unexperienced client to locate the source of a potential issue which might not even exist! With all the extra components like chargers, inverters, batteries, solar, and generators in the equation, one must be extremely meticulous and methodical to diagnose a problem in a timely manner.

Even in the residential electrical field, I remember the frustrations of spending hours to resolve a simple electrical issue. In one case, a GFCI outlet was tripped which prevented the fridge from working, but the outlet was hidden inside a kitchen cabinet behind a bunch of food items. In another, we spent not hours but days trying to locate a fault post-installation, only to find that the HVAC contractors literally cut an electrical circuit open in the panelboard to make room for their AC circuit breaker.

The moral of the story is, time is money. If you want to keep your customer happy, you need to have a deep understanding of the system you’re working with, and a methodical plan to rule out the likely issues one-by-one. Otherwise, you’ll charge a client for hours of diagnostics only to find out the problem was as easy as pushing the right button.

What It Often Looks Like

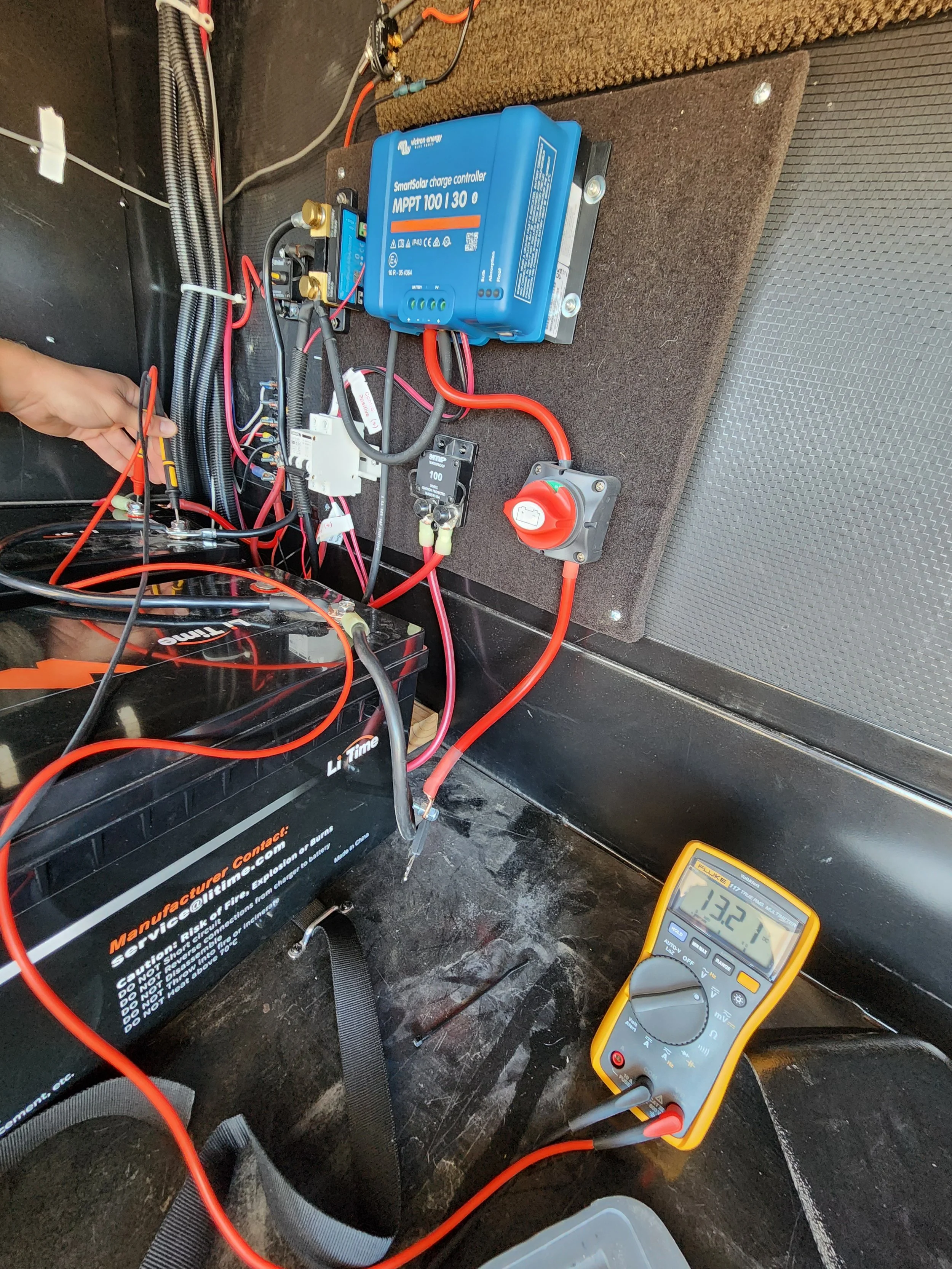

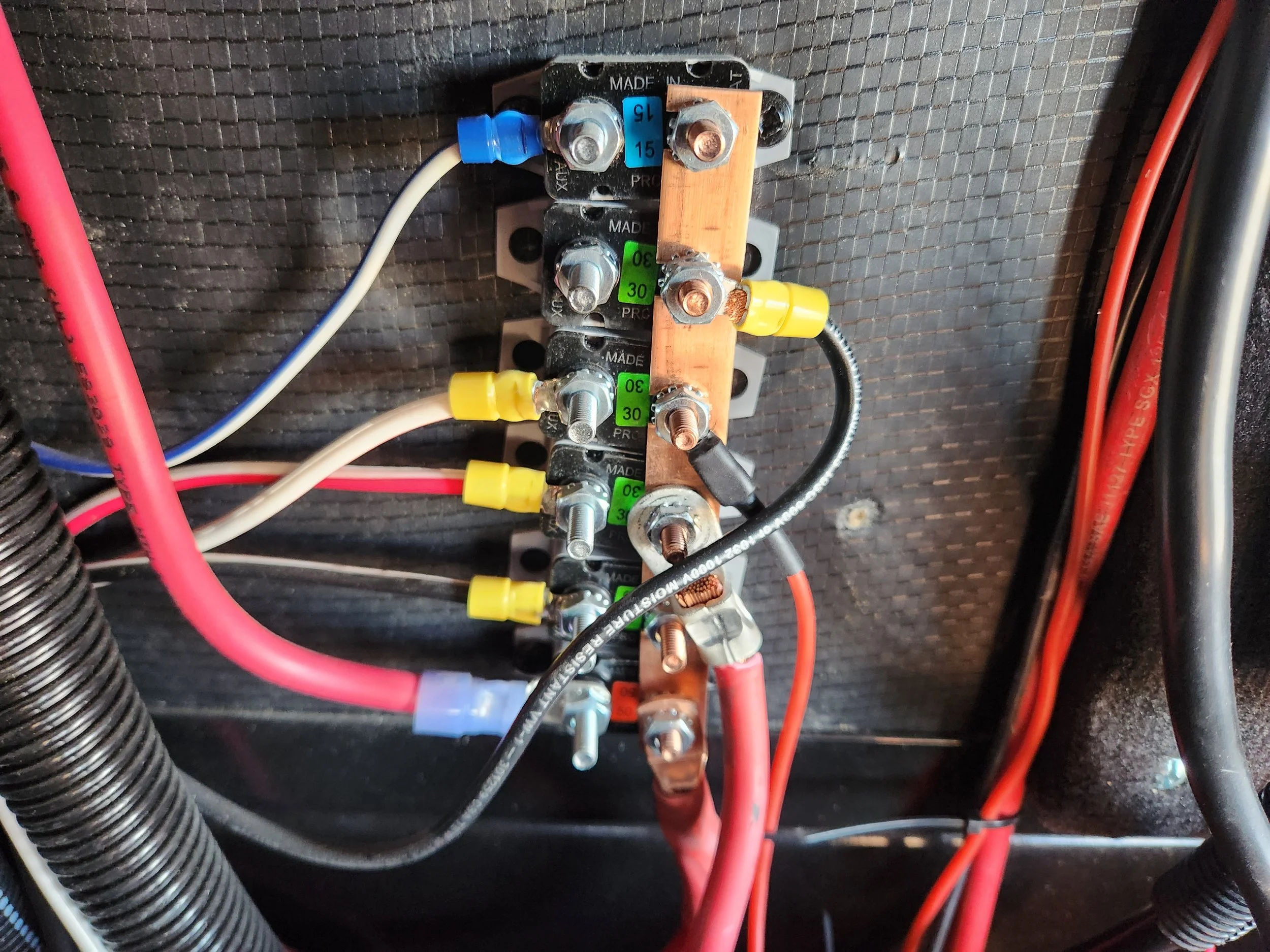

You rarely get to know what a client’s electrical system looks like until you get there. And this project was no exception. Its really frustrating on my end to go to a client’s beautiful camper or RV only to find that the previous “electrician” did a subpar job on the installation. ‘Spaghetti wiring’, as I call it, is inefficient, tough to troubleshoot, and potentially dangerous if it wasn’t designed right. In this case, the positive and negative wiring wasn’t even symmetrical. I had to take over a half hour just to figure out where current was flowing before I could even test the AC-DC charger.

Oh, and that’s another thing. This client called me because the previous tech from Solar Bill couldn’t even resolve the issue. Instead they did a classic band-aid-upsell to ‘convince’ the client that they needed a new $550 charger, and they didn’t even install it cleanly! So now it was my job to fix their mistakes in order to prove my value, without breaking the client’s wallet.

Digging into the Exam

When I first talked to this client, my immediate concern was a potential safety hazard. They had described that their battery monitor was reading an SOC of ~90%, but their battery voltage was at 12.7V. This was all occurring after their RV had been sitting for over a month, with no loads connected but solar still charging the batteries. My brain jumped to battery swelling and Lithium plating - two scenarios of internal battery damage occurring from improper battery charging in extreme temperatures. These scenarios can quickly lead to a battery fire, so that morning I was off to make sure their batteries were okay first.

Unlike Solar Bill, I performed an internal resistance test to check for lithium plating. This only takes 30 minutes for 2 batteries, and its calculated with Ohm’s Law - V=IR. Simple stuff any RV tech should know. But to my surprise, the batteries were fine at 7 milliohms internal resistance - well within the manufacturer’s specification. So if it wasn’t the batteries, then why weren’t they staying charged?

Next we made sure solar and generator power were working correctly. Solar was pretty easy - turn off all loads, measure current coming into the batteries, and compare to the rated panel wattage. Given a partly cloudy day, I read 50% power output from the panels, which was not alarming in my real-world experience. If solar was adequate, then I needed to check the generator.

Of course, spaghetti wiring decided to make this one more time-consuming. After locating the charger but not seeing any current coming into the batteries while running, it was time to trace wire. With my Fluke Networks probe and toner in hand, I sent a signal through the charger output and traced it to the battery compartment. It turns out the charger disconnect was open (which wasn’t visible from the battery compartment), so after closing the switch, the batteries were charging again. But still, this didn’t fix the issue.

Finally, after discussing the results, my client revealed a single detail which changed everything. He said his monitor wasn’t showing the refrigerator’s current draw. Was it possible that the inverter was not being routed through the Smart Shunt? After heading back to the battery compartment once more, I traced the wires and confirmed this was true! The inverter negative was tied directly to the battery lug, instead of first passing through the Smart Shunt.

This explained everything - the monitor SOC was mismatched with the battery voltage because it wasn’t seeing the bulk of the current through the system. These monitors determine SOC through ampacity, not voltage, so it won’t register the discrepancy if things were wired wrong. The funny thing is, Solar Bill actually fixed part of this problem, but not the whole thing. They had rerouted the MPPT output through the Smart Shunt, but failed to realize that the inverter was also not routed correctly.

So after moving a single wire and resetting the monitor, everything was now reading correctly. The clients once again had full control of their electrical system. The moral of the story? Sloppy wiring always leads to headaches and extra costs later on. That’s why Solar Ark takes the extra time to get installation right the first time. It might cost you $100 extra upfront for an hour of labor, but it can save you $800 in technician costs as these clients saw firsthand.

One more detail to note, is the value I provided to these clients. Maybe the fix was easy, but they didn’t just get an easy fix. With all diagnostics, we provide a written summary that covers everything we saw during the exam. The client was provided with written documentation proving the health of their batteries, the effectiveness of their solar power, diagnostics of the issue itself, and suggestions for maintenance and care to ensure the longevity of their system. That kind of expertise is like gold, ensuring my client was happy and informed.