1760W Solar Array for a Motorhome

Part 1 - Design

With Engineering Expertise

Comes Big Demands

I’ll be the first to admit, I was not expecting to get into a job like this so quickly! But when it comes to large and complex systems, good clients hunt for safety, quality, and expertise. I might not have known right off the bat that Xantrex is a big name for military-grade power electronics. But I did know that with my engineering degree and electrician experience, no system was too complicated to understand.

During our initial consultation, I had two goals - prove my expertise by understanding their system on the spot, and reveal the path forward to practical solar for these wonderful clients. We talked about their electrical loads (of which there were many) to discover what kind of energy demand we were dealing with. We also clarified goals and requirements for a solar upgrade to offset the costs of diesel generation. At the end of the day, I must have impressed these clients with the provided written summary - because they hired me quickly for this exciting design/install opportunity.

Adaptability - The Key to Effective Design

The plan was fundamentally simple. We’d replace their factory-installed 200W solar panels, PWM controller, and AGM batteries with a much larger solar array, MPPT charge controllers, and a LiFePO4 battery bank. On my end, I took the time to make sure I didn’t have to tread into AC power territory without a license. The existing batteries were connected to the Xantrex 3000W bidirectional inverter/charger, controlled by an SCP. Beyond this would be the generator, transfer switch, and shore power connections - but if we could keep the inverter, then the main focus could stay on strengthening the DC bus.

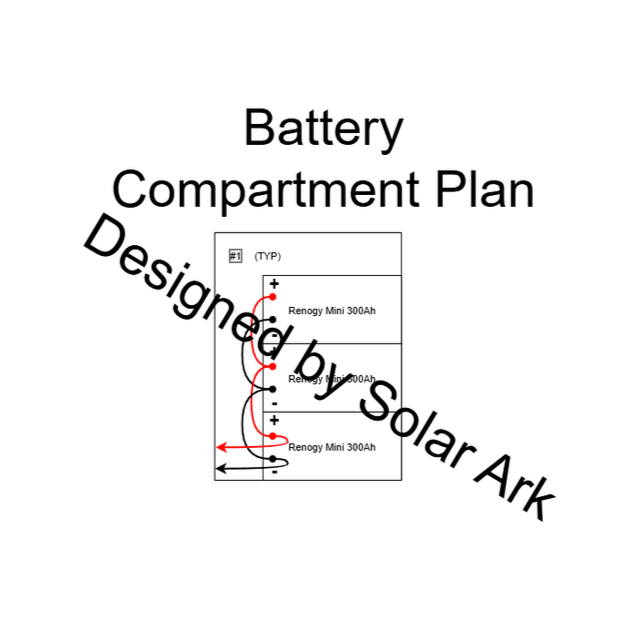

We decided to stay with a 12V system to avoid replacing the costly inverter. Lower voltage does mean higher current, but with 2x high-output MPPTs in parallel and large wiring, this wouldn’t be so bad. Especially considering that the existing AGM batteries had 4/0 cable already installed, it would mostly be an easy swap with some technical nuances to ensure safety and effectiveness.

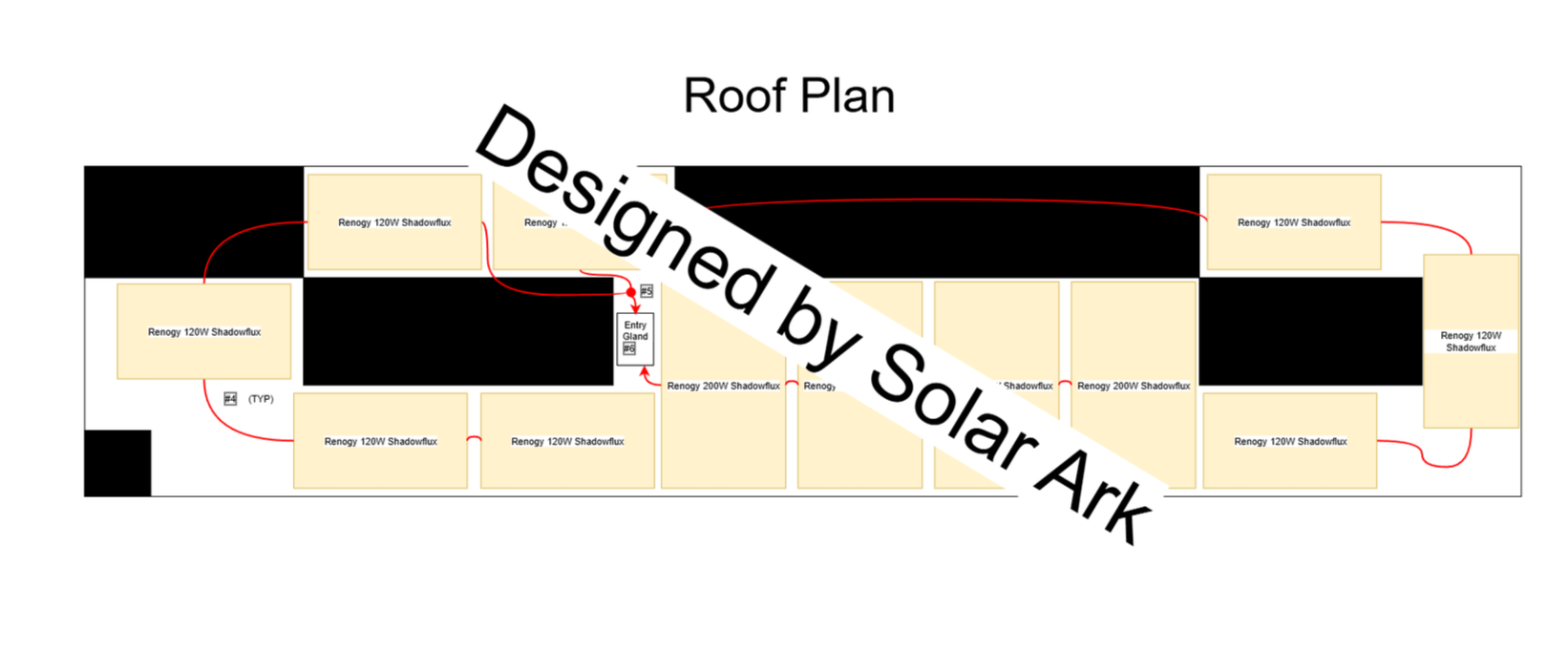

Little did I know, I’d hop on the roof for the pre-design inspection to find that the solar panels were not actually rigid panels at all! We’d have to remove these existing flexible panels, measure out roof space, and lay out the panels to get at least 1400W of solar on that roof - ideally more if possible.

From an Idea to a Design

Big project? No, not really! Once design had begun and my understanding was complete, it was just a matter of time to hammer out the details. Running some detailed calculations told me what I needed to aim for, and then it was off to laying out solar panels. We were limited on space with this project, with a smaller roof and battery compartment that really couldn’t be modified.

I started with the known available space, and shopped around for products from reputable brands to find the right fit. To my luck, Renogy happened to make some nice panels and batteries that fit perfectly. While not as high-tiered as Victron or Rich Solar, Renogy has a strong reputation for products that work well without breaking the wallet. The fact that they’re making batteries with the new prismatic LiFePO4 cells was a no-brainer for battery selection on a tight spacial budget. Paired with their new ShadowFlux technology (which is basically a fancy marketing name for extra bypass diodes), we were able to optimize a 1760W solar array with 900Ah of battery for minimizing diesel consumption while boondocking.